A toilet flush valve sits on top of the hole at the bottom of the tank and holds back the water. Whenever you flush, it opens, dumps the stored water into the bowl, and forces the waste down the drain. Then, the valve closes again so the toilet tank can fill for the next flush.

But there are different types of toilet flush valves out there, and you’ll learn about them below to know the difference and choose one accordingly.

What are the Different Types of Toilet Flush Valves?

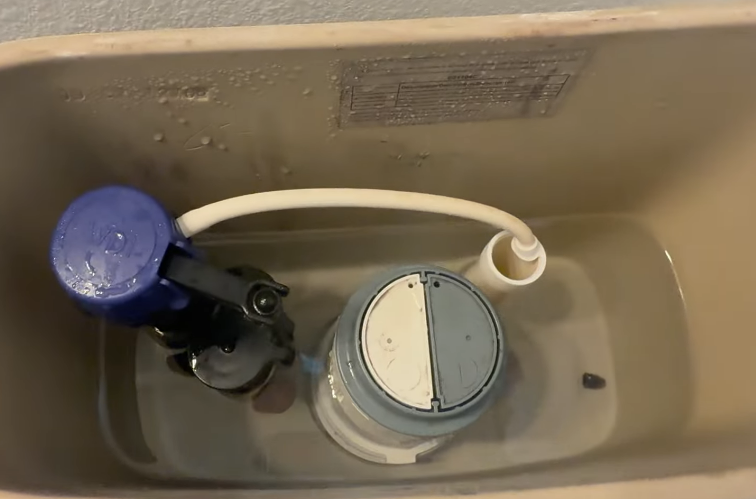

1. Dual-Flush Valve

A dual-flush valve is the system you usually see in modern toilets. Basically, instead of pushing one handle like old toilets, you get two buttons (or a split mechanism) that let you choose between a half or a full flush.

The toilet then refills for the next flush. In some older or simpler mechanical designs, this might be done with a handle that moves one way for a half flush and another for a full flush.

This gives you control over how much water is used with every flush, which ends up saving you a lot on your water bill. Some modern dual-flush toilets use as little as 3 litres (0.8 gallons) for a half flush and 6 litres (1.6 gallons) for a full flush. It is far less compared to older toilets that could use more than twice that every time.

The only drawback is that dual-flush mechanisms sometimes have more moving parts, which means repairs can be slightly trickier, but day-to-day usage is simple and reliable.

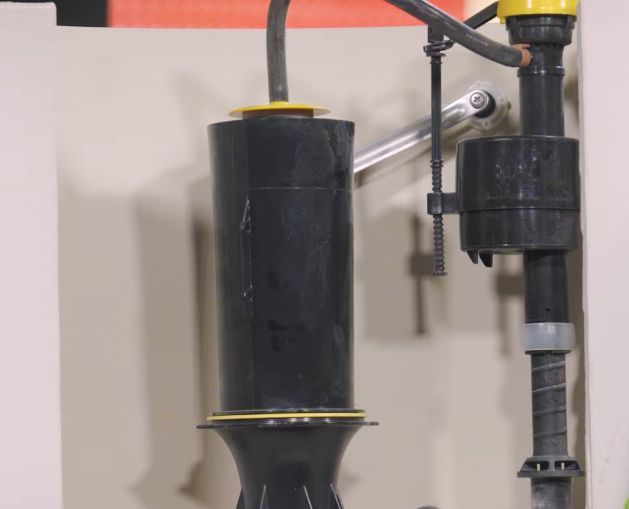

2. Tower Flush Valve

A tower flush valve works differently from the classic flapper design. Instead of just lifting a rubber flap, it lifts an entire vertical tower or cylinder straight up when you flush. That vertical movement allows water to leave the tank from all sides at once. That lets water flow into the bowl from every angle, and this makes the flush stronger and more complete than a basic flapper.

You can think of it as a tube or column inside the tank. When the toilet is not flushing, this tower sits down and seals the drain opening. When you flush, the chain linked to the handle pulls that tower upward.

Because tower flush valves drop straight down and cover the whole opening evenly, they reduce misalignment issues, although the rubber gasket at the bottom can still wear over time.

Another benefit is consistent operation. While flappers can twist, warp, or get stuck, tower valves tend to move the same way every time. You’ll mostly find these valves in newer, more efficient toilets that want strong performance while still meeting water-saving requirements.

3. Flapper-Style Flush Valve

The flapper-style valve is the classic toilet system most people have seen. Inside the toilet tank is a rubber flapper connected to a chain. When you press the button/handle, the chain pulls the flapper open, water rushes down into the bowl, and then the flapper falls back into place to seal the hole again. It’s simple, cheap, and effective, and that’s why it’s been used for decades and is still incredibly common today.

But because the flapper is made of rubber, it naturally wears out over time. Minerals in the water, cleaning chemicals, and even the constant soaking weaken it. When the flapper gets old, it doesn’t seal properly, which leads to that annoying sound where the toilet keeps refilling randomly. The good news is that the flapper is extremely easy to replace, and it costs just a few dollars and takes a couple of minutes.

4. Canister Flush Valve

A canister flush valve is like a modern upgrade of the older flapper design. When you flush, the entire canister lifts vertically, which lets water leave the tank fast and powerfully in a full 360-degree flow.

The advantage here is that these valves seal more tightly compared to flappers. So, it’s less likely to leak or allow water to slowly escape, which results in less consumption. Many newer toilets, especially higher-end brands like Kohler, use canister valves.

5. Flushometer

Flushometers are very common in commercial buildings, public restrooms, malls, restaurants, and offices. There is no tank in them that fills and empties, and they use the building’s high water pressure to send an intense burst of water directly into the bowl when you press the lever. Also, the toilet is ready for the next flush right away. There is rarely any need to repair any toilet with a flushometer.

Installing a flushometer at home usually means redoing your plumbing, and it’s costly.

6. Concealed Flush Valve

The concealed flush valve is always behind the wall. All you see is a motion sensor or a flush button. This style of toilet is popular in luxury homes, hotels, and modern bathrooms for aesthetics.

Inside the wall, the concealed tank uses a dual-flush or tower-style system, but this depends a bit on the model, too. The flush valve works the same way as exposed models, but because everything is hidden, accessing it for repairs can be a bit more difficult. If a part fails and there’s no access panel, you may need to open the wall to reach the tank. Other than that drawback, concealed toilet flush valves are an amazing choice.

7. Pressure-Assist Flush Valve

In pressure-assist flush valves, there’s a sealed plastic pressure vessel in the toilet tank. When water fills the tank, the air inside the vessel gets compressed. When you flush, the compressed air forces the water out with way more pressure than a normal gravity-fed toilet. This creates a loud but extremely powerful flush that clears waste very quickly.

These valves are great when your regular toilet doesn’t flush strongly enough, or in situations where you want fewer clogs. The good bit is that pressure-assist toilets use less water while still providing a forceful flush. The downside is that they are louder, and repairs can be more technical compared to regular flapper systems. But in terms of raw flushing performance, this type is one of the strongest options available for residential use.

How do I Know What Flush Valve I have?

To know what flush valve you have, shut off the water, open the toilet tank, and flush to empty it. Then, check the mechanism to see if it is a canister, tower, dual, or flapper flush valve.

To figure out the size of the flapper flush valve, look at the flapper and measure it from one end to the other. A flapper that is 3 inches across is a 2-inch flush valve. A flapper that is 4 inches across means the toilet has a 3-inch flush valve. It’s the quickest way to identify the size.

Conclusion

Now that you know the different types of toilet flush valves, choose the toilet that has the one that best fits your needs. For any kind of toilet installation and repair, contact California Coast Plumbers now!